A Beginner’s Guide to Factory Automation

Manufacturing has been in a constant state of development since the 19th century, when the Industrial Revolution saw the rise of machinery. Once we discovered ones and zeros can be used to transmit data, the computer was born and that was a springboard to bigger and better things. Electronics began to merge with robotics to produce systems to carry out specific manufacturing tasks and this leads to a boost in productivity.

Control Systems

The PLC programmable logic controller is a vital component that enables fast processing in real time; leading companies such as Delta offer tailored solutions for industrial automation. AI is merging with electronics to manage systems, while the robotics sector is keeping pace by building robotic arms to carry out intricate tasks. If you run a manufacturing business and would like to learn more about automation, start with a Google search to find a company that provides tailored systems.

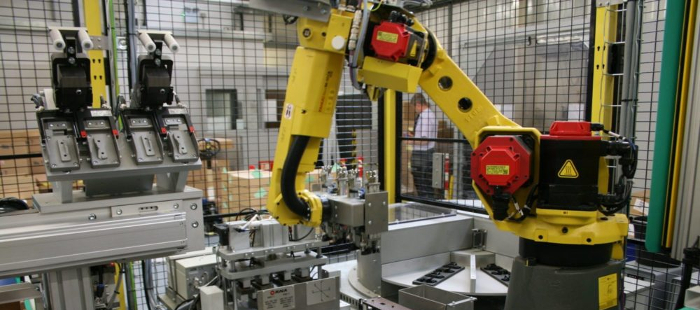

The Rise of Robotics

Factory automation would not be possible without robotics and this cutting-edge industry is surging ahead, providing innovative solutions that are tailored to the operation. Delicate electronic tasks can be quickly carried out with the state-of-the-art robotic systems of today; search online for providers of such systems and find out how you can transform your production line and boost output. For the very best in robotic tech, take a look at some of the YouTube videos of Tesla’s factories to get an idea of where we are regarding industrial automation, while giant corporations like Amazon are also leading the field.

Quality Control

This is one area that we thought would always be the domain of employees; advancements in AI means QC can be fully automated, with zero errors. This also means a safer working environment and a cleaner factory floor, while the need for labour is greatly reduced. A factory with automated QC can produce far more than if their QC was handled by a team of employees and for some factories, QC is a bottleneck that slows down the production line.

Significant Investment

To transform a manufacturing plant to full automation is a big investment, yet one that pays big long-term dividends. The demand for employees is drastically reduced, which means lower running costs and eventually, the business recoups the investment and profits soar. The transformation can be gradual, with specific processes focused on and when they are running smoothly, the next process can be set up and so on, until you have full automation.

Industrial automation and AI have merged to provide a fully automated production process that will eventually take the human out of the loop. Every factory owner should be looking into automation, which can be a gradual change, starting with the most basic processes and boosting output.